As electric vehicles (EVs) gain popularity, dedicated auto body repair facilities are increasingly vital. These facilities face unique challenges from EVs' advanced technology, including heavy battery packs and specialized paint jobs. They must invest in skilled technicians, cutting-edge technologies like CAD software and robotic welding systems, and digital workflow management to handle the distinct repairs these vehicles require. By embracing these strategies, auto body repair facilities can ensure safe, high-quality EV repairs while meeting evolving industry standards and customer expectations.

As electric vehicles (EVs) gain popularity, auto body repair facilities must adapt to meet their unique challenges. This article explores the evolving role of these facilities in EV maintenance, delving into the specific needs and technologies required for efficient repairs. From understanding the distinct issues posed by EVs’ advanced systems to adopting innovative practices and tools, this introduction sets the stage for a comprehensive guide on optimizing auto body repair services for the modern electric vehicle landscape.

- Understanding the Unique Challenges of Electric Vehicle Repairs

- The Role of an Auto Body Repair Facility in EV Maintenance

- Best Practices and Technologies for Efficient EV Auto Body Repair Services

Understanding the Unique Challenges of Electric Vehicle Repairs

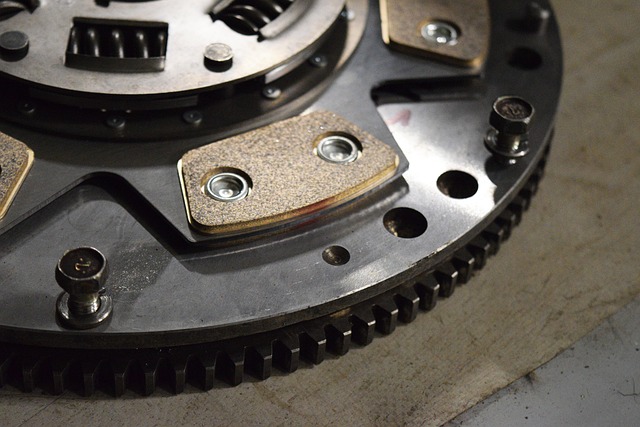

Electric vehicles (EVs) present unique challenges for auto body repair facilities compared to their conventional counterparts. As technology advances, so do the intricate details and specialized components within EV bodies. A dedicated auto body repair facility for EVs must stay abreast of these evolving trends to provide accurate and efficient services. For instance, repairing or replacing battery packs, which are heavier and more sensitive than traditional fuel systems, requires precise handling and specific safety protocols.

Moreover, many modern EVs feature advanced paint technologies, such as advanced coating materials and intricate design patterns, demanding skilled technicians adept in paintless dent repair techniques. Unlike conventional car body repairs, EV repairs often involve working with high-voltage components and complex electronics, necessitating specialized training and equipment to ensure both safety and effectiveness. This calls for a facility that understands the nuances of EV construction and can adapt its services accordingly, providing top-notch auto body repair while catering to the unique needs of electric vehicles.

The Role of an Auto Body Repair Facility in EV Maintenance

An auto body repair facility plays a pivotal role in the maintenance and upkeep of electric vehicles (EVs). As EVs gain popularity, specialized services are needed to address unique challenges posed by their advanced technology and intricate design. These facilities are equipped with the necessary tools and expertise to handle various types of repairs, from minor dent removal and paintwork to more complex structural damage.

Collision repair services form a significant part of an auto body repair facility’s offerings, ensuring that EV owners can get their vehicles back on the road safely and efficiently. With skilled technicians trained in EV-specific repairs, these facilities can effectively manage car damage repair while preserving the vehicle’s original equipment and systems. This not only guarantees top-notch cosmetic restoration but also maintains the environmental benefits of electric mobility by minimizing waste and maximizing the use of existing components.

Best Practices and Technologies for Efficient EV Auto Body Repair Services

In the realm of auto body repair facilities, catering to Electric Vehicle (EV) repairs requires a unique approach and adoption of cutting-edge technologies. The best practices for efficient EV auto body repair services involve staying abreast of advancements in battery technology and charging infrastructure. Facilities should invest in specialized tools designed for precise, non-destructive EV component removal and reinstallation, ensuring minimal damage to sensitive batteries and electrical systems during the collision repair process.

Additionally, integrating digital workflow management systems streamlines operations by facilitating better communication, tracking, and coordination among team members. These systems enable auto body repair facilities to offer faster turnaround times, improved accuracy in repairs, and enhanced customer satisfaction. Key technologies include computer-aided design (CAD) software for precise measurements and panel replacement, as well as robotic welding systems that boost efficiency while maintaining high quality standards in bumper repair and other automotive collision repair tasks.

An auto body repair facility that caters to electric vehicle (EV) repairs plays a pivotal role in ensuring these innovative vehicles’ longevity and safety. By understanding the unique challenges posed by EV repairs, such as battery replacement and advanced electronics, these facilities can offer specialized services. Adopting best practices and integrating cutting-edge technologies enables efficient, accurate, and eco-friendly auto body repair for EVs, fostering a sustainable future on the road.